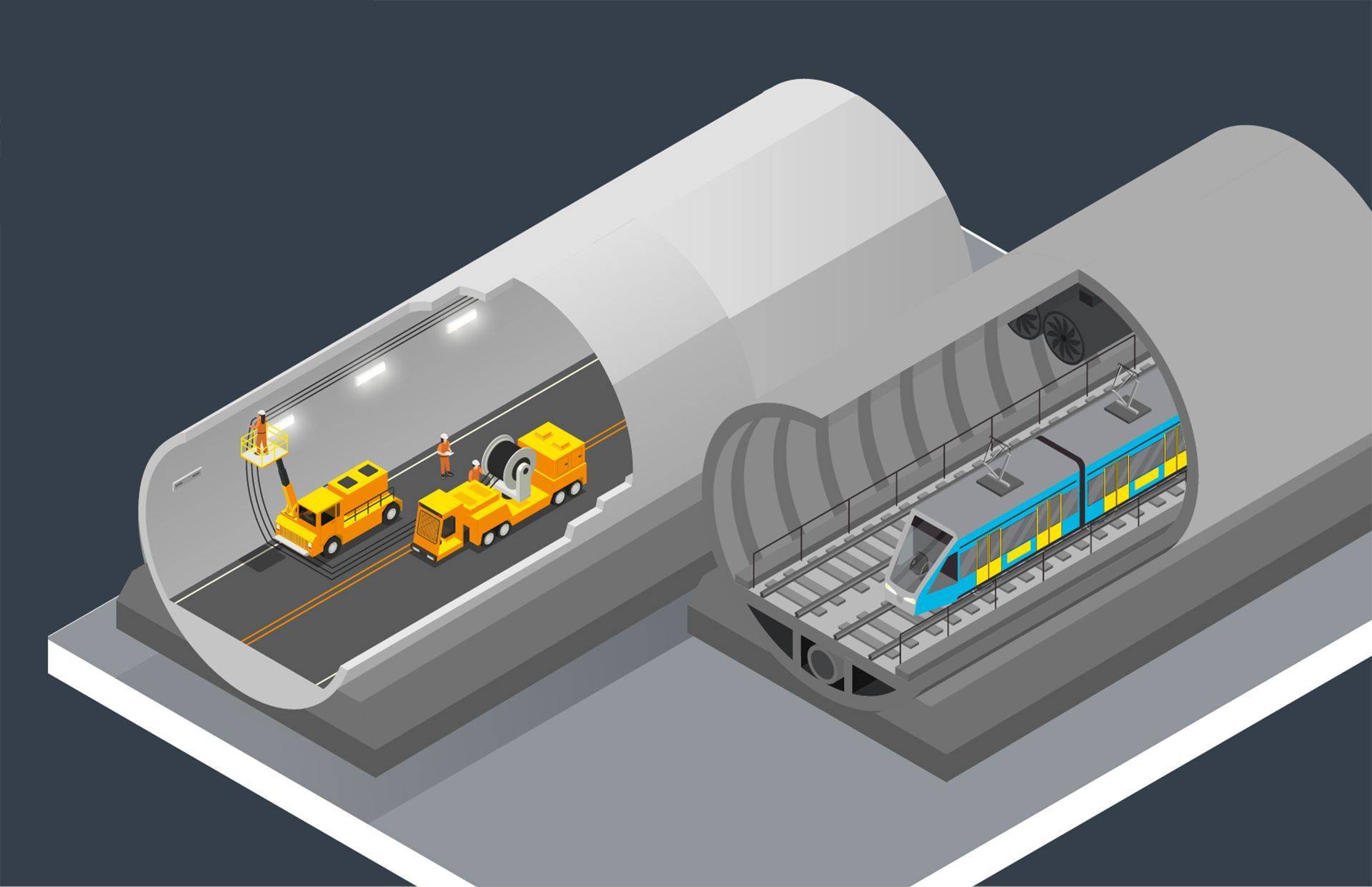

The City Rail Link project is set to be a game-changer for Auckland’s public transport with 3.45 kilometers of underground rail tunnels that will more than double the city’s rail capacity.

With our Link Alliance design partners WSP and Tonkin & Taylor, we are pushing the boundaries of what’s possible using BIM on linear infrastructure. The team has improved efficiency and reduced risk on the project, and at the same time enabled greater visibility of the overall project design.

Common data environment – The digital engineering team is using a common data environment, to enable more than 200 project designers and engineers to work in a single online location with the latest updated designs. The geographically dispersed engineers, across eight different teams, can collaborate and live-share over 50 different models, and simultaneously interrogate and review the current design via a web browser, without any additional software or hardware requirements.

New design processes – We employed a combination of traditional building information modeling (BIM) processes, as well as some newer parametric design and generative design processes. This reduced tunnel design modeling time from weeks to hours. When designing the cross-passages (short tunnels that connect two parallel tunnels) in the main tunnels, we used a completely parametric design approach.

**The power of parametric design **– This is our ability to regenerate the model based on design changes in just minutes. In addition, the objects in our parametric approach are designed to address different stages of the project, providing the right level of detail at the right time. A cross-passage is a highly complicated element that must be placed based on the physical arrangement of the precast tunnel segments (rotation, tapering, key segment position, etc).

Visual programming and computational design have been critical in performing a theoretical calculation of the tunnel boring machine ring placement based on an algorithm that aims to minimise the diversion from the design alignment.

Parametric design or modeling is the creation of a digital model based on a series of pre-programmed rules or algorithms known as parameters. This means that the model, or elements of it, are generated automatically by internal logic arguments rather than being manually manipulated by engineers and/or modelers.

Generative design – We have also deployed generative design within the tunnel design to create the kinematic envelope. This is the space allocated for the safe passage of the moving trains through the tunnel. Engineers used the modeled kinetic envelope to check that the design met the requirements and ensure that no element would be positioned in a way to obstruct the safe passage of the train. This generative design approach saved a considerable amount of time, by reducing several iterations which normally involve interaction with many different disciplines and technical experts. Generative design is an iterative design process that involves a program that will generate a certain number of outputs that meet predetermined constraints.

The project team continues to push new boundaries with the use of digital engineering processes and computational design and is now applying these techniques to other parts of the CRL project to further enhance the design and construction.